Home - Segment Design

Segment Design

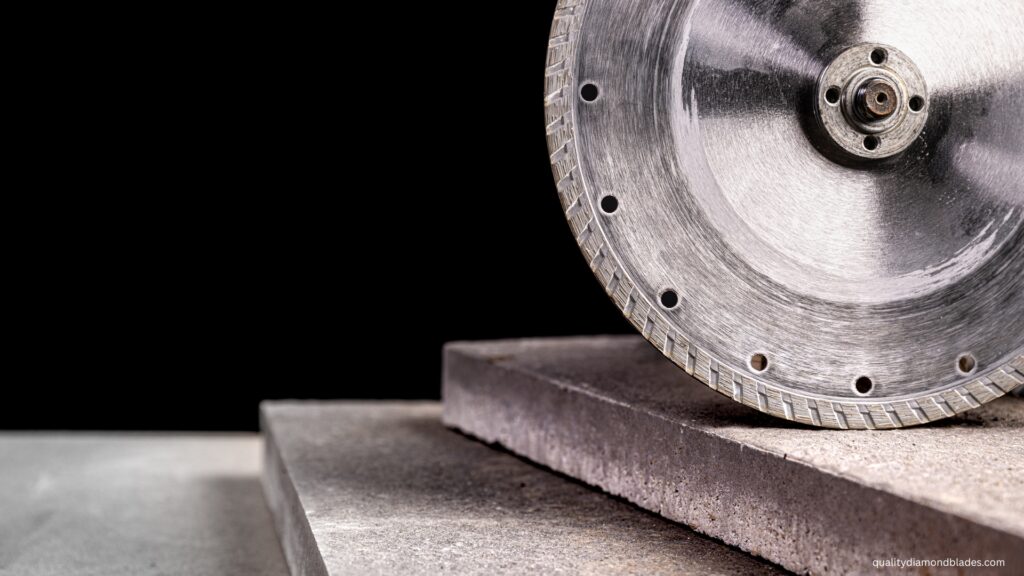

The segment design of a diamond blade has a direct impact on how fast it cuts, how clean the cut is, and how long the blade lasts. Whether you’re cutting concrete, tile, pavers, or reinforced materials, choosing the correct rim style and segment pattern makes all the difference. This guide breaks down the major rim types, segment configurations, and the best uses for each—so you get better performance and longer blade life with every cut.

Rim Type Breakdown

1. Segmented Rim

Best for: Concrete, masonry, block, brick, dry cutting

Segmented blades feature individual diamond segments with gullets between them. These gullets push air through the blade for cooling and allow dust to escape, making segmented blades ideal for tougher, abrasive materials.

Benefits:

- Fast cutting on hard or abrasive materials

- Handles dry cutting better than most blade types

- Ideal for handheld saws and walk-behind saws

2. Turbo Rim

Best for: Stone, tile, masonry, mixed materials

Turbo blades combine continuous material with angled or serrated edges to drive air across the surface. This results in faster cooling and smoother cuts.

Benefits:

- Cleaner edge than segmented blades

- Faster cutting than continuous rim

- Works well on natural stone, porcelain, and harder materials

3. Continuous Rim

Best for: Tile, porcelain, ceramics, glass

A continuous rim provides a smooth edge with no interruptions, making it the preferred choice for delicate materials where chip-free precision is essential. These blades perform best with water cooling.

Benefits:

- Smoothest cut quality

- Best option for wet tile saws

- Prevents chipping on porcelain and fine tile

Segment Height Comparison

Segment height determines blade lifespan and durability. Taller segments generally mean more usable diamond material.

| Segment Height | Typical Lifespan | Best Use |

|---|---|---|

| 7–10mm | Shorter life, budget-friendly | Light masonry, DIY cuts |

| 10–12mm | Standard professional height | Concrete, block, pavers |

| 12–15mm | Extended life, heavy duty | Cured concrete, demolition |

| 15mm+ | Premium longevity | Reinforced concrete, high-abrasion cuts |

Segment Pattern Differences

Drop Segments

Best for preventing blade warping and reducing binding on deep cuts. These include a lowered center section that helps keep the blade straight under heavy load.

U-Slots

The “U” shaped gullets improve cooling and dust removal. Helpful when cutting dry or when using smaller saws with less power.

Laser-Welded Segments

Made for high-heat, heavy-duty cutting. Segments are bonded by laser, allowing them to withstand high RPMs, deep cuts, and demanding materials.

Sintered Segments

Pressed and fused with heat. Common on budget blades. Suitable for lighter cutting but not recommended for high-stress or high-heat work.

Vacuum Brazed Segments

Diamonds are brazed to the surface, creating sharp, aggressive cutting action. Great for metal, steel, rebar, and mixed demolition materials.

- FREE Shipping over $100

- Engineered for Maximum Durability

- Precision Cuts Every Time

- Fits All Major Saw Brands

- Trusted by Industry Professionals

- Money-Back Satisfaction Guarantee

- Fast, Reliable Customer Support

- Bulk Discounts Available

- Perfect for Wet or Dry Cutting

- 25583 Avenue Stanford, Santa Clarita, CA 91355 United States

- Mon - Fri: 9am - 5pm Sat 9-3pm

Bonus: How to Choose the Right Segment Design

If you want a fast way to match blade type to your job, follow this rule:

If speed is the priority → go segmented

If clean finish is the priority → go continuous

If you need speed + smoothness → go turbo

If cutting mixed materials → choose vacuum brazed

If cutting deep concrete or rebar → choose laser-welded soft-bond segmented