Can these diamond blades cut both ferrous and non-ferrous metals?

Yes. Many of our metal-cutting blades are engineered to handle both ferrous (steel, iron) and non-ferrous (aluminum, brass, copper) metals. Always check the blade spec for material compatibility.

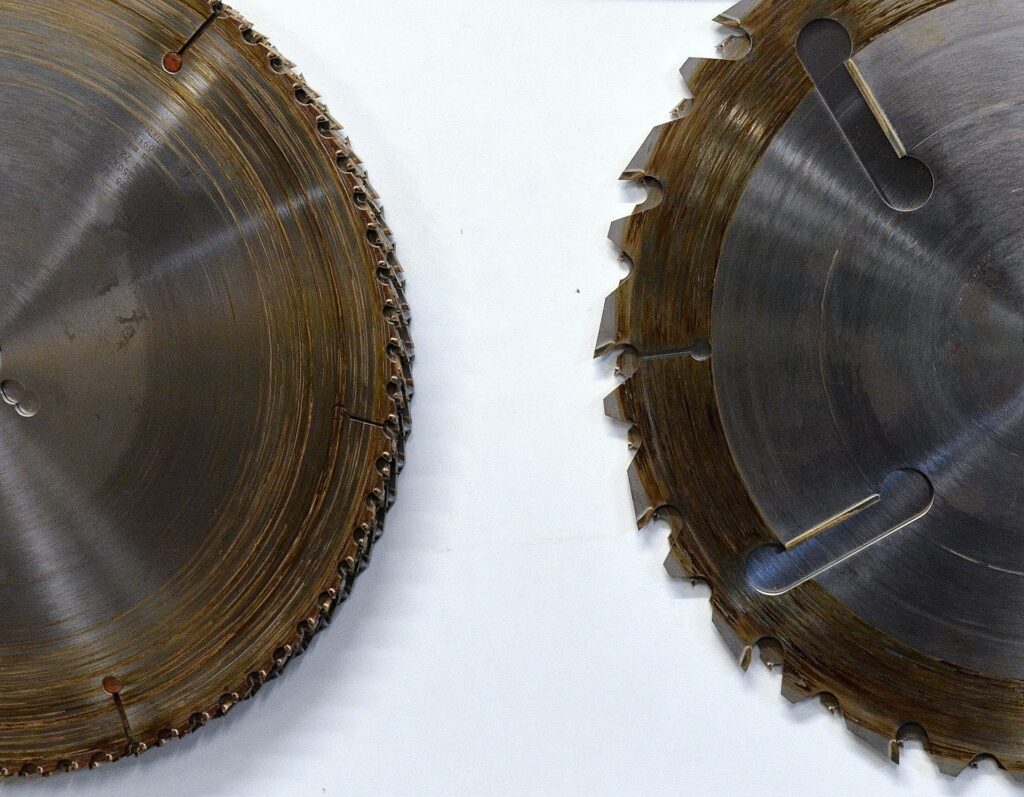

Are they better than standard abrasive cut-off wheels?

Yes. Compared with bonded abrasive wheels, diamond metal blades offer far longer life, cleaner cuts, less vibration and fewer blade changes—thereby reducing downtime and total cost.

Can I use them for both wet and dry cutting?

Many of our blades support both wet and dry cutting. Dry cutting is common for portability, while wet cutting reduces dust and heat—especially helpful when cutting heavy or thick metal materials.

Is there a size or arbor requirement I need to check?

Yes. Ensure that the blade’s diameter, arbor size (e.g., 7/8”), and maximum RPM rating match your tool. Using a blade outside its rated parameters can shorten life or compromise safety.

How do I choose the right blade for my job?

Consider material type (thickness, steel vs stainless vs cast iron), saw type (angle grinder vs chop saw), cut depth, wet vs dry environment, and whether you need a blade optimized for speed or for longevity. If unsure, contact our team for tailored guidance.