-

-

What are the benefits of choosing a 14-inch diamond saw blade?

-

How do material-specific blades differ from multi-purpose blades?

-

What’s the difference between premium and standard diamond blades?

-

Why should I consider laser-welded technology in diamond saw blades?

-

Are heavy-duty applications suitable for all types of diamond saw blades?

-

Diamond Saw Blade Maintenance: Can you provide tips to extend its life?

-

Why should I invest in quality diamond saw blades over cheaper alternatives?

-

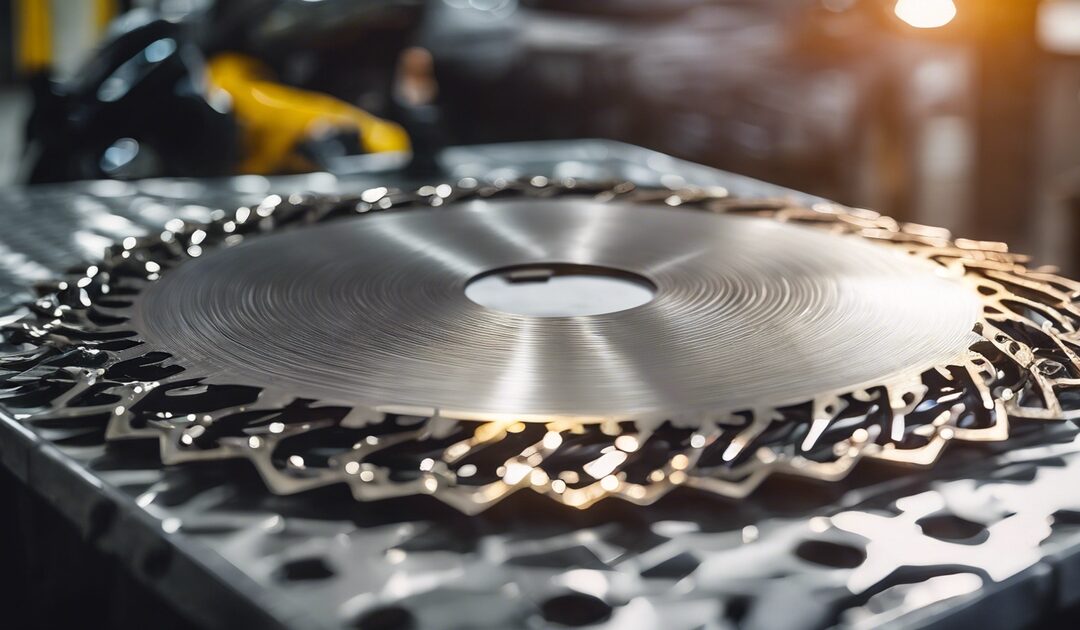

In the bustling world of construction and renovation, the choice of tools can make or break your project. Enter the 14 diamond saw blade – a game-changer for professionals and DIY enthusiasts alike. Unlike standard blades, this powerhouse cuts through the toughest materials with precision and ease, transforming daunting tasks into manageable ones. It stands in stark contrast to its counterparts, offering durability that outlasts and performance that outshines, making it an indispensable tool in your arsenal. Whether you’re slicing through concrete or delicately shaping marble, understanding how to harness the full potential of this blade can elevate your work from good to exceptional. Let’s dive into what makes the 14 diamond saw blade a cut above the rest.

Key Takeaways

- Opt for the Right Size: The 14-inch diamond saw blade offers a balance of cutting depth and versatility, making it suitable for a range of applications from construction to DIY projects.

- Material Matters: Selecting a blade designed specifically for the material you plan to cut (concrete, asphalt, tile, etc.) can significantly improve both performance and the lifespan of the blade.

- Quality Over Cost: Investing in premium blades over standard ones can yield better cutting efficiency and longer durability, ultimately saving money in the long run.

- Versatility Is Key: Multi-purpose blades, while not as specialized, provide a practical solution for users who cut various materials, offering flexibility and reducing the need for multiple blades.

- Innovative Technology Enhances Performance: Blades featuring laser-welded technology offer stronger bonds between the segments and core, leading to higher performance and safety in heavy-duty applications.

- Maintenance Extends Life: Regular maintenance, including checking for wear and ensuring proper installation, can extend the life of your diamond saw blade, ensuring it remains a valuable tool in your arsenal.

Choosing Diamond Blades

Blade Types

Diamond blades come in various forms, each designed for specific materials and cutting conditions. Among these, the dto SMP14P stands out as a premium diamond segmented saw blade. Its construction allows it to tackle a wide range of cutting tasks efficiently.

Different blades are tailored for different materials. This variety ensures that whether you’re cutting through soft marble or tough granite, there’s a blade built for the job. The choice of blade type directly impacts the quality of the cut and the speed of completion. Hence, selecting the right blade type is crucial for achieving desired results without damaging the material or the tool.

Material Compatibility

The dto SMP14P blade shines when it comes to compatibility with hard materials. It’s well-suited for cutting through hard concrete, asphalt, brick, and block. This versatility makes it an invaluable tool in construction and renovation projects.

Material compatibility plays a significant role in determining which blade to use. A mismatch between blade and material can lead to poor performance, faster wear-out, or even safety hazards. Therefore, understanding the material you intend to cut is key to selecting a suitable diamond saw blade. For optimal cutting results, always match your blade to the material at hand.

Wet vs Dry Cutting

One notable feature of the dto SMP14P is its capability for both wet and dry cutting. Wet cutting offers benefits like dust suppression and cooling of the blade, extending its lifespan and improving worker safety. On the other hand, dry cutting is valued for its convenience and suitability in situations where water is not readily available.

Choosing between wet and dry cutting depends on several factors including job site conditions, material being cut, and personal preference. Each method has its own set of advantages that make it preferable under certain circumstances.

RPM Considerations

The maximum RPM rating of 5460 for the dto SMP14P highlights its efficiency in high-speed cutting operations. Operating within this RPM range ensures optimal performance while preserving the integrity of both the blade and the material being cut.

It’s critical to adhere to recommended RPM settings to avoid potential damage to your diamond saw blade or creating safety risks during operation. Exceeding these limits can result in decreased efficiency, increased wear on the blade, and heightened risk of accidents.

14-Inch Blade Advantages

Cutting Depth

The segment height of 10mm (.394″) plays a crucial role in understanding the cutting depth of a 14-inch diamond saw blade. This measurement is not arbitrary. It directly influences how deep the blade can cut into materials. The larger the diameter and segment height, the deeper the potential cut. For many projects, adequate cutting depth is essential. It allows for more versatility in applications, from slicing through thick slabs of concrete to making precise cuts in tiles.

A deep cut means fewer passes are needed, saving time and wear on the blade. This efficiency is vital for both professionals and DIY enthusiasts who demand precision and speed in their work.

Versatility

The dto SMP14P 14-inch diamond saw blade shines in its multi-purpose use. Its design allows it to effortlessly cut through various materials, including concrete, brick, block, stone, and more. This adaptability makes it an invaluable tool for a wide range of projects.

Its suitability for both professional construction tasks and home DIY projects cannot be overstated. Having a versatile blade means you’re prepared for any job that comes your way, reducing the need to purchase multiple blades for different materials. This not only saves money but also space in your toolkit.

Arbor Size

The dto SMP14P blade features a 1-inch arbor size, a critical aspect for ensuring a secure fit onto the saw. Matching the arbor size with your saw’s specifications is paramount for maintaining blade stability during operations. A snug fit prevents wobbling and ensures clean, accurate cuts every time.

Arbor size impacts more than just stability; it affects overall cutting performance and safety. A properly fitted blade reduces vibrations, minimizing fatigue during extended use and lowering the risk of accidents.

Material Specific Blades

Hard Concrete

The dto SMP14P blade stands out for its efficiency in slicing through hard concrete. Hard concrete presents a significant challenge due to its density and abrasive nature. Yet, the right blade can turn this daunting task into a manageable one.

This blade’s segment height and specialized cutting type are key. They allow it to penetrate hard materials with less wear and tear. Its design ensures durability and a longer lifespan, making it a top choice for professionals dealing with hard concrete.

Asphalt

When it comes to asphalt, the dto SMP14P blade proves equally competent. Cutting asphalt involves unique challenges, such as preventing tar from sticking to the blade and ensuring adequate cooling during operation.

The segmented design of this blade is crucial for preventing overheating. It allows air to flow through, keeping the blade cool. This design feature makes it ideal for tackling asphalt projects without the risk of premature wear or damage.

Masonry

Masonry materials vary widely, from bricks to stone. The dto SMP14P blade demonstrates remarkable versatility across these materials. Diamond segments play a pivotal role in its effectiveness. They enable smooth, efficient cuts through even the toughest masonry.

Its design contributes significantly to achieving clean and precise cuts in masonry work. For professionals seeking reliability and precision, this blade is an invaluable tool.

Premium vs Standard Blades

Segment Height

Premium blades, like the 14 diamond saw blade, often feature a 10mm segment height. This design choice directly impacts their cutting depth and longevity. A taller segment allows these blades to cut through thicker materials more effectively. It means they don’t wear down as quickly, offering more value over time.

The balance between segment height and cutting speed is crucial. A higher segment can slow down the cut slightly but ensures the blade lasts longer and can tackle tougher jobs. It’s about finding the right tool for your specific needs, ensuring efficient operation without sacrificing performance.

Durability

The dto SMP14P blade stands out for its durable construction. It’s designed for long-term use, thanks in part to its high-quality diamond segments. These segments are key to the blade’s longevity, as they resist wear and tear better than lower-quality options.

Durability also hinges on proper usage and maintenance. Even the toughest blade will suffer if misused or neglected. Regular cleaning and storing it in a dry place can significantly extend its life. Thus, investing in a premium blade also means committing to taking care of it to maximize its durability.

Cutting Speed

A critical factor in choosing a saw blade is its cutting speed. The 14 diamond saw blade is engineered for optimal speed without compromising quality. The material being cut and the characteristics of the blade itself influence this speed.

Different materials require different approaches. For instance, cutting through concrete is not the same as slicing through tile. The right blade selection can lead to efficiency gains, making your job easier and faster while still achieving clean cuts.

Multi-Purpose Blades

Material Range

The dto SMP14P blade stands out for its versatility. It can slice through a wide array of materials, from concrete and brick to asphalt and limestone. This adaptability makes it an invaluable tool in any builder’s or contractor’s arsenal.

Using a single blade for multiple materials offers significant benefits. It reduces the need for multiple tools, saving both space and money. Moreover, switching blades less frequently saves time on the job. The blade’s performance remains consistent across various material densities and hardness. This consistency ensures that projects proceed smoothly, without the hassle of changing tools for different materials.

Efficiency

Efficiency defines the dto SMP14P blade’s cutting capabilities in both wet and dry conditions. It excels by maintaining high speed and precision while minimizing material waste. These factors are crucial for measuring a blade’s effectiveness.

For professional contractors, efficiency translates to faster completion times and reduced project costs. DIY enthusiasts benefit from the precision cutting that elevates their projects to a professional standard. The ability to cut efficiently under varied conditions underscores the blade’s value in diverse work environments.

Laser-Welded Technology

Strength Benefits

Laser-welded technology in 14-inch diamond saw blades brings unparalleled strength. These blades can handle the most challenging cutting jobs with ease. Their design incorporates a robust bonding process. This ensures the diamond segments remain firmly attached under extreme conditions.

The blade’s strength is crucial for achieving clean cuts swiftly. It reduces work time significantly. Users can expect consistent performance across various materials, from concrete to asphalt. This versatility stems from the blade’s innovative engineering.

Safety Features

Safety is paramount when operating high-performance tools like the 14-inch laser-welded diamond saw blade. Its design includes segmented edges. These segments play a vital role in preventing overheating, a common issue that can lead to blade failure and accidents.

Choosing the right blade for specific materials enhances safety and efficiency. For example, using a blade not suited for cutting through reinforced concrete can result in damage to both the tool and material, posing serious safety risks.

Best practices for safe operation are essential to follow:

- Ensure the blade operates at the correct RPM.

- Use the recommended cutting method for each material type.

These guidelines help minimize risks and ensure optimal performance.

Heavy-Duty Applications

Reinforced Concrete

The 14 diamond saw blade shines when it comes to cutting through reinforced concrete. Its design specifically targets the challenges that this tough material presents. Reinforced concrete, with its embedded steel bars, poses a significant obstacle for most blades. However, the dto SMP14P blade is up to the task.

Its segment height and diamond quality are critical in overcoming these challenges. The taller segments allow for deeper cuts in one pass, reducing work time. High-quality diamonds ensure the blade remains sharp and effective, even when cutting through tough steel reinforcements. This combination makes the dto SMP14P blade an ideal choice for projects involving reinforced concrete.

Metal Cutting

While the 14 diamond saw blade excels at slicing through concrete, asphalt, and masonry, its capabilities extend to metal cutting on a limited basis. It’s important to note that while it can handle some metal cutting tasks, assessing the blade’s suitability is crucial before attempting such applications.

Metal cutting demands specific features from a blade, including thermal resistance and wear tolerance. For occasional cuts in metal materials embedded within concrete or masonry, the dto SMP14P can perform adequately. However, for extensive metal cutting operations, specialized blades designed explicitly for metal are necessary. These blades ensure efficiency and longevity in projects where metal is the primary material being cut.

Maintenance Tips

Blade Cleaning

Keeping your 14 diamond saw blade, specifically the dto SMP14P, in top condition starts with regular cleaning. This is crucial for maintaining its cutting efficiency, especially after heavy-duty applications. Material build-up on the blade not only hampers performance but can also shorten its lifespan.

For effective cleaning, first, let the blade cool down. Then, use a soft brush and mild detergent to gently remove any debris from the diamond segments. For tougher build-up, soaking the blade in warm water before brushing can help loosen the material. Always ensure you’re wearing protective gloves to avoid injuries during this process. This method not only preserves the cutting edge but also prepares it for its next use.

Storage Solutions

How you store your dto SMP14P blade significantly impacts its longevity and readiness for future tasks. Proper storage means keeping it in a dry and safe place where it’s protected from accidental damage. Moisture is a big enemy of diamond blades as it can lead to rust and corrosion, even on high-quality blades like the dto SMP14P.

To maintain blade sharpness and prevent damage, consider hanging the blade on a wall-mounted hook or placing it in a dedicated storage case when not in use. These methods keep the blade off the ground and away from potential hazards that could dull or damage its cutting surface. Remember, investing time in proper storage solutions pays off by extending your blade’s lifespan and ensuring it’s ready for action whenever you need it.

Why Choose Quality Diamond Blades

Product Quality

The dto SMP14P blade stands out for its premium quality and construction. This blade is designed with precision to ensure it meets the highest standards of performance. Its superior craftsmanship not only enhances cutting efficiency but also extends the lifespan of the blade.

Product quality significantly impacts both overall cutting performance and user satisfaction. A high-quality diamond saw blade like the dto SMP14P ensures clean, precise cuts every time, reducing waste and saving time on projects. Furthermore, its recognition as an Amazon’s Choice product underscores its reliability and high-quality standards among users and experts alike.

Customer Support

For the dto SMP14P blade, customer support is readily available. This ensures that users can easily get help with product inquiries or troubleshooting issues. Having accessible support makes a big difference in the overall user experience.

Good customer service is crucial in enhancing user satisfaction. It reassures users that they have a reliable resource for help when needed, making their investment feel more secure. This level of support reflects the company’s commitment to their customers’ success with their products.

Value for Money

The dto SMP14P blade offers exceptional value for money due to its versatility, durability, and outstanding performance. Investing in this high-quality blade means less frequent replacements are needed, which saves money over time.

Its suitability for a wide range of applications makes it a cost-effective solution for many projects. Whether cutting through concrete, asphalt, or tile, this blade maintains its efficiency and effectiveness, providing great value in both residential and commercial settings.

Final Remarks

Choosing the right 14-inch diamond saw blade makes all the difference in your cutting projects. You’ve seen the benefits, from precision cuts with material-specific blades to the durability of premium options and the versatility of multi-purpose blades. Laser-welded technology and heavy-duty capabilities ensure your tasks are not just completed but mastered, while maintenance tips keep your tools in top shape. Quality isn’t just a choice; it’s a necessity for efficiency and longevity in your work.

Now’s the time to elevate your toolkit. Don’t settle for less when you can have the best. Opt for quality diamond blades that meet your needs and surpass expectations. Your projects deserve precision, durability, and efficiency. Make the switch today and see the difference quality makes. Your work will thank you.

Frequently Asked Questions

What are the benefits of choosing a 14-inch diamond saw blade?

14-inch diamond blades offer superior cutting depth, making them ideal for larger projects. Their size allows for more efficient cuts in thicker materials.

How do material-specific blades differ from multi-purpose blades?

Material-specific blades are designed for optimal performance on specific materials, enhancing cutting precision and lifespan. Multi-purpose blades, while versatile, may not offer the same level of efficiency or durability on certain materials.

What’s the difference between premium and standard diamond blades?

Premium diamond blades are engineered with higher quality diamonds and bonding materials, providing longer life and faster cutting speeds. Standard blades are more affordable but might not deliver the same performance or longevity.

Why should I consider laser-welded technology in diamond saw blades?

Laser-welded technology offers superior strength and durability to the blade segments, ensuring they stay attached under heavy use. This technology also allows for safer operation and reduced blade wear.

Are heavy-duty applications suitable for all types of diamond saw blades?

Not all diamond saw blades are suited for heavy-duty applications. Selecting a blade designed specifically for heavy use ensures better performance, safety, and longevity.

Can you provide maintenance tips for extending the life of a diamond saw blade?

To extend your blade’s life, regularly check for wear or damage, ensure proper cooling during use, and store it in a dry place. Also, rotating your blade can promote even wear.

Why should I invest in quality diamond saw blades over cheaper alternatives?

Investing in quality diamond saw blades ensures better cutting performance, reliability, and safety. Quality blades also offer a longer lifespan, reducing the need for frequent replacements and ultimately saving money over time.