Introduction: The Power of Diamond Blades

We live in a world where cutting technology has a significant impact on our daily lives. From construction projects to home improvements, having the right cutting tools is crucial. One of the most sought-after and versatile cutting tools is the diamond blade. But what makes these blades so special? Are diamond blades strong? In this article, we’ll delve into the world of diamond blades and explore their strength, durability, and various applications.

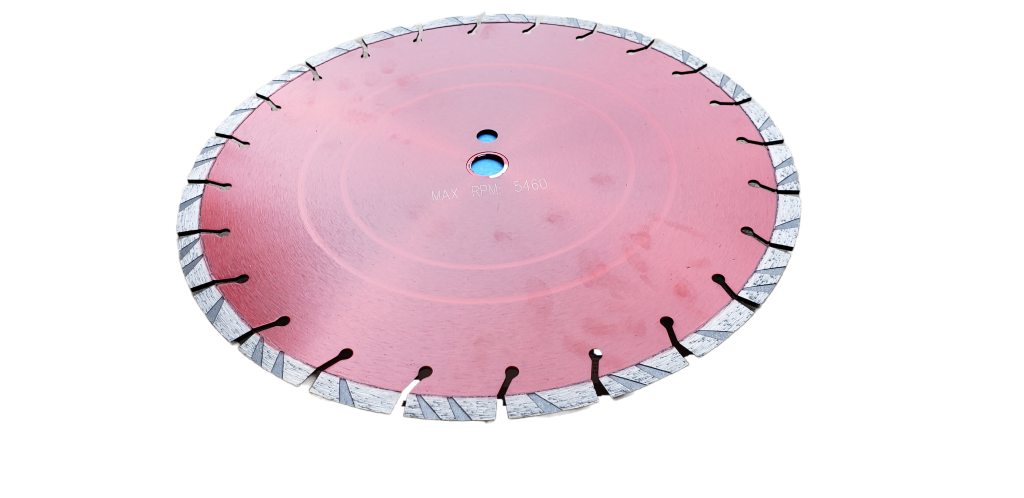

1. What are Diamond Blades?

1.1 Understanding the Basics

Diamond blades are cutting tools specifically designed to cut through various materials using diamonds as the cutting medium. Diamonds, being the hardest known material on Earth, make these blades extremely strong and durable. The diamonds are embedded into the metal matrix of the blade, which allows for a sharp and efficient cutting edge.

1.2 Types of Diamond Blades

There are two main types of diamond blades:

- Sintered diamond blades: These blades are made by combining diamond crystals with metal powders under high heat and pressure. This process bonds the diamonds to the metal matrix, creating a strong and durable cutting edge.

- Electroplated diamond blades: These blades are made by electro-chemically bonding the diamond crystals to a metal substrate. This process creates a thinner layer of diamond coating, resulting in a sharper cutting edge but with less durability than sintered blades.

2. Strength and Durability: The Benefits of Diamond Blades

2.1 Unparalleled Hardness

Diamonds are known for their incredible hardness, which is a key factor contributing to the strength of diamond blades. With a hardness rating of 10 on the Mohs scale, diamonds are the hardest known material, making them ideal for cutting through various materials with ease.

2.2 Longevity

Diamond blades offer unparalleled longevity compared to other cutting tools. Their diamond-infused cutting edges ensure that they remain sharp and effective even after extended use. This makes them a cost-effective choice for professionals and DIY enthusiasts alike.

2.3 Versatility

Diamond blades are highly versatile and can be used to cut through a wide range of materials, including:

This versatility makes them a popular choice for construction, demolition, and home improvement projects.

3. The Factors Affecting Diamond Blade Strength

3.1 Diamond Concentration

The concentration of diamonds in a blade plays a significant role in its strength and cutting efficiency. Higher diamond concentrations result in a more durable and longer-lasting blade.

3.2 Bond Hardness

The bond hardness of a diamond blade refers to the hardness of the metal matrix holding the diamonds in place. A harder bond will generally be more durable, while a softer bond may allow for a faster cutting speed but reduced blade life.

3.3 Blade Thickness

The thickness of a diamond blade can also affect its strength and cutting ability. Thicker blades offer greater durability, while thinner blades may provide a smoother and faster cut but with reduced blade life.

4. Proper Use and Maintenance: Maximizing Diamond Blade Strength

4.1 Choosing the Right Blade

Selecting the correct diamond blade for your specific application is crucial in ensuring optimal strength and performance. Be sure to consider factors such as material type, cutting speed, and blade life when selecting a diamond blade.

4.2 Proper Cutting Techniques

Using the proper cutting techniques can significantly impact the strength and longevity of your diamond blade. Always follow the manufacturer’s guidelines for cutting speed, depth, and blade cooling to maximize blade life.

4.3 Regular Maintenance

Regularly inspect and maintain your diamond blade to ensure it remains strong and efficient. Check for any signs of wear or damage, such as missing or worn diamonds, and clean the blade regularly to remove debris and buildup.

5. Safety Considerations: Protecting Yourself and Your Blade

5.1 Personal Protective Equipment (PPE)

When using diamond blades, always wear appropriate PPE, including safety glasses, gloves, ear protection, and a dust mask to protect yourself from potential hazards.

5.2 Proper Blade Storage

Store your diamond blades in a dry, cool location, away from direct sunlight or extreme temperatures. This will help prevent damage and maintain their strength and durability.

Conclusion: The Strength of Diamond Blades

In conclusion, diamond blades are indeed strong, durable, and versatile cutting tools that can handle various materials with ease. Their strength comes from the unparalleled hardness of the diamonds embedded in the blade, as well as factors such as diamond concentration, bond hardness, and blade thickness. Proper use, maintenance, and safety precautions will ensure that your diamond blade remains strong and efficient for years to come.

Frequently Asked Questions (FAQs)

Q1: Are diamond blades suitable for all types of cutting applications?

A1: Diamond blades are highly versatile and can be used for a wide range of materials. However, it’s essential to choose the right blade for your specific application to ensure optimal performance and blade life.

Q2: Can I use a diamond blade with any type of saw?

A2: Diamond blades can be used with various types of saws, such as angle grinders, circular saws, and tile saws. Always ensure that the blade is compatible with your saw and follow the manufacturer’s guidelines for proper use.

Q3: How do I know when my diamond blade needs to be replaced?

A3: Signs that your diamond blade may need to be replaced include a decrease in cutting efficiency, excessive vibration during use, or visible damage, such as missing or worn diamonds.

Q4: How can I extend the life of my diamond blade?

A4: Proper use, maintenance, and storage will help prolong the life of your diamond blade. Follow the manufacturer’s guidelines for cutting techniques, blade cooling, and regular inspections to ensure optimal performance.

Q5: Are diamond blades more expensive than other types of cutting tools?

A5: While diamond blades may have a higher upfront cost compared to other cutting tools, their longevity and durability often make them a cost-effective choice in the long run.