Curious about the disparity between a diamond blade and a carbide-tipped blade? These cutting tools have distinct characteristics that impact their performance. Understanding these differences is crucial for selecting the right tool for your project. While diamond blades excel in cutting hard materials like concrete and stone, carbide-tipped blades are more versatile and cost-effective for various applications. Dive into this comparison to grasp which blade suits your needs best.

Key Takeaways

- Choose Wisely: Understand the differences between diamond blades and carbide-tipped blades to select the right one for your cutting needs.

- Consider Performance: Evaluate the cost and performance aspects to make an informed decision based on your specific requirements.

- Prioritize Quality: Opt for quality diamond blades for durability, efficiency, and precision in your cutting tasks.

- Regular Maintenance: Maintain your chosen blade regularly to prolong its lifespan and ensure optimal performance.

- Cost Efficiency: Balance initial costs with long-term benefits by selecting a blade that offers both quality and cost-effectiveness.

- Tailored Selection: Tailor your blade choice to the materials you frequently work with to achieve the best results.

Blade Basics

Material Composition

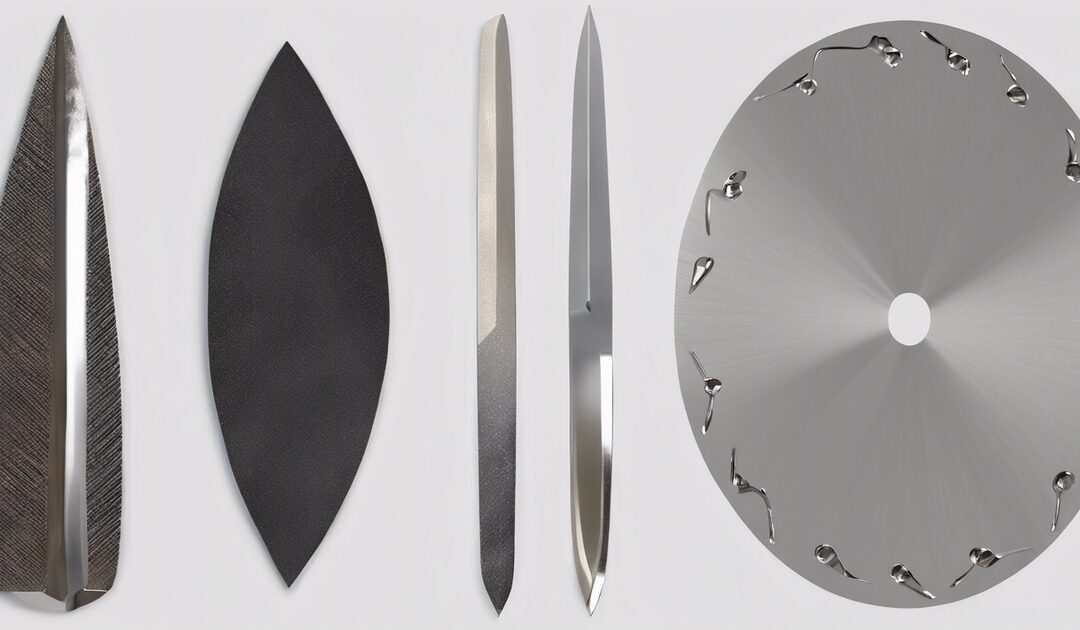

Diamond blades consist of polycrystalline diamond (PCD), offering exceptional wear resistance for cutting hard materials. In contrast, carbide tipped blades are a blend of carbide and other materials optimized for specific cutting tasks. The material composition sets diamond blades apart from carbide tipped blades.

Cutting Applications

Diamond blades excel in machining abrasive materials like concrete and stone, providing precision and efficiency. On the other hand, carbide tipped blades face challenges with continuous cutting of homogeneous materials, limiting their application range. The cutting applications vary significantly between diamond blades and carbide tipped blades across different materials.

Longevity and Durability

Diamond blades boast impressive longevity and durability, maintaining a clean finish until they become dull. Conversely, carbide tipped blades encounter durability issues during prolonged cutting operations due to wear. When comparing longevity and durability, diamond blades outperform carbide tipped blades significantly.

Diamond Blades Explained

Construction Process

Polycrystalline diamond (PCD) tools are manufactured through a high-pressure, high-temperature laboratory process. This involves creating a synthetic diamond layer on a carbide substrate. On the other hand, carbide tipped blades are constructed by fusing carbide with other materials like steel. The fusion process enhances the blade’s durability and cutting capabilities. The construction processes of diamond blades and carbide tipped blades differ significantly in terms of materials used and manufacturing techniques.

Unique Advantages

Diamond blades offer unique advantages such as providing a high-quality finish on various materials and being cost-effective per linear foot machined. Their exceptional hardness makes them ideal for cutting hard materials like concrete and asphalt. Conversely, carbide tipped blades excel in specific cutting applications where diamond blades may not be suitable, such as cutting softer materials like wood or plastic. Each type of blade offers distinct advantages based on the material being cut and the required finish.

Ideal Use Cases

Diamond blades are ideal for machining abrasive materials due to their superior hardness and wear resistance. They are commonly used in high-volume workflows where precision cutting is crucial. In contrast, carbide tipped blades shine in cutting applications that require precision and versatility. For instance, they are well-suited for woodworking projects that involve intricate cuts and shaping. Examples of ideal use cases for diamond blades include cutting concrete, masonry, and tile, while carbide tipped blades are perfect for woodworking, metal cutting, and general construction tasks.

Carbide Tipped Blades Unveiled

Manufacturing Techniques

Polycrystalline diamond (PCD) tools are created using advanced manufacturing techniques involving high pressure and high temperature to bond diamond particles. These tools are ideal for industrial cutting applications requiring precision and durability. On the other hand, carbide tipped blades are manufactured by brazing a piece of carbide to the tip of a steel saw blade. This process ensures a strong bond between the carbide and the steel, making the blade suitable for various cutting tasks.

The manufacturing techniques for diamond blades focus on embedding diamond crystals within a metal matrix through a sintering process. This results in a robust cutting tool capable of handling tough materials. In contrast, carbide tipped blades are crafted by grinding tungsten carbide into precise shapes before attaching them to the blade body. This method enhances the blade’s cutting efficiency.

Key Benefits

Diamond blades offer exceptional wear resistance due to the hardness of diamonds, allowing for prolonged use without dulling. They reduce the need for sanding after cutting, saving time and effort. On the other hand, carbide tipped blades provide excellent heat resistance and maintain sharpness over extended periods, making them ideal for specific cutting applications that require precision.

When comparing key benefits, diamond blades excel in durability and longevity, while carbide tipped blades shine in maintaining sharpness during prolonged use. Both types of blades offer unique advantages based on their composition and design, catering to different cutting requirements effectively.

Optimal Applications

Diamond blades are best suited for machining abrasive materials like concrete, asphalt, or stone due to their superior hardness and wear resistance properties. They are commonly used in construction and masonry industries for precise cutting tasks. In contrast, carbide tipped blades perform exceptionally well in woodworking applications where clean cuts are essential, thanks to their sharp edges and heat resistance capabilities.

The optimal applications for diamond blades include cutting through hard materials that would quickly wear down traditional steel blades. Conversely, carbide tipped blades find their niche in woodworking projects where precision cuts are crucial. Each type of blade is tailored to excel in specific scenarios, providing efficient solutions for diverse cutting needs.

Cost Analysis

Initial Investment

Polycrystalline diamond (PCD) tools require a significant initial investment due to their high-quality materials and manufacturing process. However, the long-term cost-effectiveness of PCD tools is remarkable as they offer exceptional durability and cutting performance. On the other hand, carbide tipped blades have a lower initial cost, making them more accessible for users with budget constraints. The value proposition of carbide tipped blades lies in their balance between affordability and decent performance. When comparing the initial investment needed for diamond blades and carbide tipped blades, it’s essential to consider the specific needs and budget constraints of the user.

Maintenance Expenses

Maintaining polycrystalline diamond (PCD) tools involves costly sharpening procedures due to their hardness and unique composition. The maintenance costs associated with PCD tools are higher compared to traditional blade types. Conversely, maintaining and sharpening carbide tipped blades is less expensive as they are easier to sharpen and maintain. The maintenance expenses for diamond blades can be a significant factor to consider when evaluating overall operating costs compared to carbide tipped blades.

Lifespan Considerations

Diamond blades are known for their impressive lifespan, offering extended usability and durability even in demanding cutting applications. The durability of diamond blades makes them a preferred choice for users looking for long-lasting cutting solutions. In contrast, carbide tipped blades have limitations in lifespan, requiring more frequent replacements due to wear and tear. Understanding the lifespan considerations between diamond blades and carbide tipped blades is crucial in determining the overall cost-effectiveness and efficiency of these cutting tools.

Performance Comparison

Cutting Speed

Diamond blades excel in cutting speed, especially in high-volume workflows, due to their ability to withstand continuous use. They slice through materials swiftly, making them ideal for industrial settings. On the other hand, carbide tipped blades offer decent cutting speeds across various applications, providing a balance between speed and precision. When compared, diamond blades generally outperform carbide tipped blades in terms of cutting speed.

Precision Levels

Precision levels achieved with diamond blades are exceptional, ensuring clean finishes and accurate cuts even on the most delicate materials. These blades maintain sharpness for longer periods, enhancing their precision capabilities. In contrast, carbide tipped blades maintain good precision levels across different cutting scenarios but may require more frequent sharpening to retain accuracy. Comparatively, diamond blades offer superior precision levels when compared to carbide tipped blades.

Material Versatility

Diamond blades showcase remarkable material versatility, particularly excelling in machining abrasive materials and composites without losing efficiency or durability over time. Their robust construction allows them to tackle a wide range of materials effectively. Conversely, carbide tipped blades have limitations in material versatility based on their composition, being more suitable for specific materials. When evaluating material versatility, diamond blades stand out for their ability to handle diverse materials compared to carbide tipped blades.

Selecting the Right Blade

Project Requirements

Diamond blades excel in projects involving abrasive materials and require high-volume cutting due to their durability and strength. They are ideal for tasks like cutting concrete, asphalt, or stone efficiently.

Carbide tipped blades shine in projects that demand precision cuts on less abrasive materials such as wood or plastic. These blades are effective for detailed woodworking tasks or cutting softer materials accurately.

- Examples of project requirements:

- Diamond Blades: Concrete road construction, stone countertop fabrication.

- Carbide Tipped Blades: Fine woodworking, PVC pipe cutting.

Budget Constraints

Investing in polycrystalline diamond (PCD) tools may pose initial budget challenges; however, their long-term cost-effectiveness through extended durability makes them a valuable investment for heavy-duty projects.

Carbide tipped blades offer a more cost-effective solution upfront compared to diamond blades. While they may require more frequent replacements, their affordability makes them a practical choice for smaller projects or occasional use.

- Comparison of budget constraints:

- Diamond Blades: Higher initial cost but long-term savings.

- Carbide Tipped Blades: Lower initial cost but potentially higher replacement frequency.

Equipment Compatibility

Diamond blades require equipment with sufficient power and stability to handle the high-speed cutting of hard materials effectively. They are best suited for use in robust saws or specialized cutting machines.

Carbide tipped blades are compatible with a wider range of cutting equipment and machinery due to their versatility across various materials. From handheld circular saws to miter saws, these blades offer flexibility in different work settings.

- Comparison of equipment compatibility:

- Diamond Blades: Specialized machinery for hard material cutting.

- Carbide Tipped Blades: Versatile compatibility with various cutting tools and machines.

Maintenance Tips

Cleaning Practices

To maintain diamond blades, clean them with a mixture of water and mild detergent after each use. Avoid harsh chemicals. For carbide tipped blades, wipe them with a damp cloth to remove residue. Use a wire brush for stubborn debris.

For diamond blades, ensure they are completely dry before storing to prevent rusting. Store in a cool, dry place away from direct sunlight. In contrast, carbide tipped blades should be stored in a protective case to avoid chipping or dulling.

When it comes to cleaning, diamond blades require more gentle care due to their delicate nature compared to carbide tipped blades which can withstand tougher cleaning methods.

Storage Solutions

Store diamond blades vertically in a rack to prevent warping. Keep them in their original packaging or use blade guards for added protection. For carbide tipped blades, store horizontally in a dry environment to avoid moisture exposure.

Ensure that the storage area for diamond blades is free from humidity and temperature fluctuations. Conversely, protect carbide tipped blades from humidity by using desiccant packets in the storage container.

The storage solutions differ between diamond blades and carbide tipped blades based on their material composition and susceptibility to environmental factors.

Sharpening Techniques

To sharpen polycrystalline diamond (PCD) tools, use a diamond wheel dresser or file. For carbide tipped blades, utilize a silicon carbide grinding wheel for sharpening. Sharpening frequency depends on usage intensity.

For maintaining sharpness, periodic sharpening is crucial for PCD tools while carbide tipped blades may require less frequent sharpening sessions. The sharpening techniques vary based on the blade material and cutting requirements.

Quality Diamond Blades Spotlight

Product Range

Diamond blades offer a wide array of options tailored to various cutting needs and materials. They come in different sizes, rim types, and bond formulations for versatility. On the other hand, carbide tipped blades provide specialized solutions for specific cutting tasks such as masonry or metal.

-

Diamond blades:

- Available in sizes ranging from 4 inches to over 36 inches.

- Offered with segmented, continuous rim, turbo, and other designs for different applications.

-

Carbide tipped blades:

- Designed with carbide teeth for enhanced durability when cutting through tough materials like concrete or steel.

When comparing the product ranges of diamond blades and carbide tipped blades, it’s evident that diamond blades excel in versatility across a broader range of materials, while carbide tipped blades shine in durability for more specialized applications.

Customer Satisfaction

Customers using diamond blades often praise their exceptional performance and longevity. The sharpness and precision of diamond blades contribute to high customer satisfaction levels. Conversely, users of carbide tipped blades appreciate their resilience when tackling demanding cutting tasks.

-

Feedback on diamond blades:

- Users admire the clean cuts and extended lifespan provided by diamond blades.

-

Satisfaction rates with carbide tipped blades:

- Customers value the durability and robustness of carbide tipped blades for challenging cutting jobs.

In terms of customer satisfaction, both diamond blades and carbide tipped blades receive positive feedback; however, diamond blades are favored for their overall performance across a wider range of materials.

Industry Reputation

Diamond blades have established a strong industry reputation based on their consistent performance, reliability, and superior quality. Their presence in various industries like construction and stone fabrication underscores their credibility. Carbide tipped blades are respected within the cutting tools sector for their durability and efficiency.

-

Reputation of diamond blades:

- Widely recognized for delivering precise cuts with minimal chipping or damage.

-

Market presence of carbide tipped blades:

- Known for their ability to withstand tough cutting conditions without losing sharpness.

Comparing the industry reputations of diamond blades versus carbide tipped blades reveals that while both are esteemed within the industry, diamond blades stand out for their exceptional precision and reliability across diverse applications.

Making the Choice

Assessing Needs

To determine the right blade choice, assess your cutting needs first. Consider the material, depth, and frequency of cuts.

For diamond blades, evaluate if you often cut hard materials like concrete or asphalt. Check for blade specifications.

When considering carbide tipped blades, ensure they match your cutting tasks by reviewing their durability and suitability.

Consulting Experts

Seek advice from professionals when opting for diamond blades to ensure precise selection for specific projects.

Consulting experts is crucial for choosing carbide tipped blades due to their varying applications and features.

Expert guidance helps in understanding the nuances between diamond blades and carbide tipped ones.

Quality Assurance

Quality assurance is key when selecting diamond blades to ensure consistent performance and longevity.

Manufacturers follow strict quality checks during production and testing of carbide tipped blades.

Compare the quality standards of both types to make an informed decision on blade durability.

Summary

You now know the key differences between diamond blades and carbide-tipped blades, from their construction to performance and cost. Understanding these distinctions is crucial when selecting the right blade for your cutting needs. Remember to consider factors like material, budget, and expected usage before making your choice. Proper maintenance will also extend the lifespan of your blade, ensuring optimal performance. Quality diamond blades can make a significant difference in the precision and efficiency of your cutting projects. Make an informed decision based on these insights to enhance your cutting experience.

Frequently Asked Questions

What are the key differences between a diamond blade and a carbide-tipped blade?

Diamond blades are designed for cutting hard materials like concrete and stone, while carbide-tipped blades are better suited for softer materials like wood and plastic. Diamond blades offer superior precision and durability, whereas carbide-tipped blades provide versatility at a lower cost.

Which blade type is more cost-effective in the long run, diamond or carbide-tipped?

In the long run, diamond blades tend to be more cost-effective due to their durability and ability to maintain sharpness over time. While carbide-tipped blades may have a lower upfront cost, they wear out faster and require more frequent replacements, making them less cost-effective in the long term.

How do I choose between a diamond blade and a carbide-tipped blade based on performance?

If you need high precision and durability for cutting hard materials, opt for a diamond blade. For general-purpose cutting tasks on softer materials with occasional use on harder surfaces, a carbide-tipped blade would be sufficient. Consider your specific cutting needs to determine which blade offers optimal performance.

What maintenance tips are crucial for maximizing the lifespan of both diamond and carbide-tipped blades?

To extend the lifespan of diamond blades, ensure proper cooling during use to prevent overheating. For carbide-tipped blades, regular cleaning to remove debris buildup and periodic sharpening are essential maintenance practices. Following manufacturer guidelines for usage and storage can significantly increase the longevity of both types of blades.

Are there any specific considerations when selecting between quality diamond blades available in the market?

When choosing quality diamond blades, consider factors such as bond type, segment design, and diamond concentration for optimal performance. Select a blade that matches your cutting application requirements to ensure efficient and precise results. Investing in a high-quality diamond blade can enhance cutting speed and overall productivity.