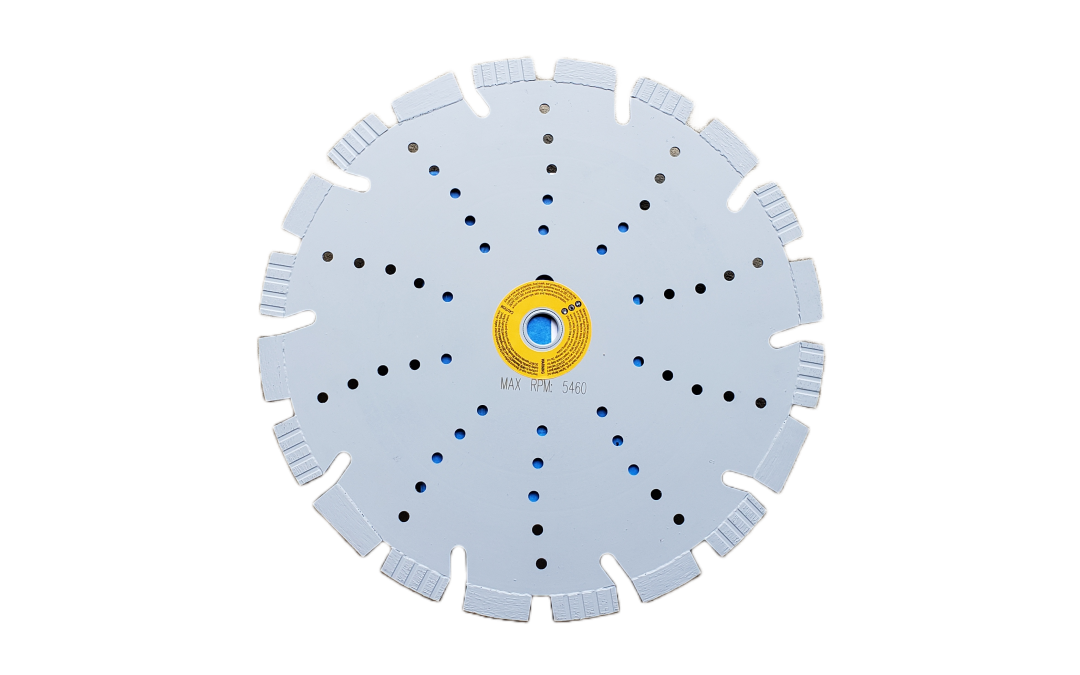

If you’re in the market for a diamond blade, you may be wondering about the different types of bonding agents that are available. Diamond blade bonding agents play a critical role in the performance and durability of the blade. In this article, we’ll discuss the different types of bonding agents that you can choose from, and what you should consider when selecting the right one for your application.

Metal Bonding Agents

Metal bonding agents are the most commonly used bonding agents for diamond blades. They are made from a mixture of metals, such as copper, cobalt, or nickel, which are mixed with diamond grit and other fillers to create a strong, durable bond. Metal bonding agents are ideal for cutting through hard materials, such as concrete, stone, and ceramics. They are also capable of producing a high-quality finish.

Resin Bonding Agents

Resin bonding agents are made from a mixture of resin and diamond grit. These bonding agents are ideal for cutting through soft materials, such as asphalt and plastic. They are also commonly used for polishing applications. Resin bonding agents are less durable than metal bonding agents, but they produce a smoother cut and are less likely to leave scratches on the material being cut.

Electroplated Bonding Agents

Electroplated bonding agents are made from a single layer of diamond grit that is attached to the blade using an electroplating process. These bonding agents are ideal for cutting through materials that are prone to chipping, such as glass and composites. They are also commonly used for cutting through softer materials, such as wood and plastic.

Factors to Consider When Choosing a Bonding Agent

When selecting a bonding agent for your diamond blade, there are several factors that you should consider. These include the material that you will be cutting, the type of cut that you need to make, and the finish that you require. You should also consider the speed and precision that you require from your blade, as well as the overall cost.

Conclusion

In conclusion, the type of bonding agent that you choose for your diamond blade will have a significant impact on its performance and durability. Metal bonding agents are the most commonly used, and they are ideal for cutting through hard materials. Resin bonding agents are best suited for cutting through soft materials and producing a high-quality finish. Electroplated bonding agents are ideal for cutting through materials that are prone to chipping. When selecting a bonding agent, you should consider the material that you will be cutting, the type of cut that you need to make, and the finish that you require.