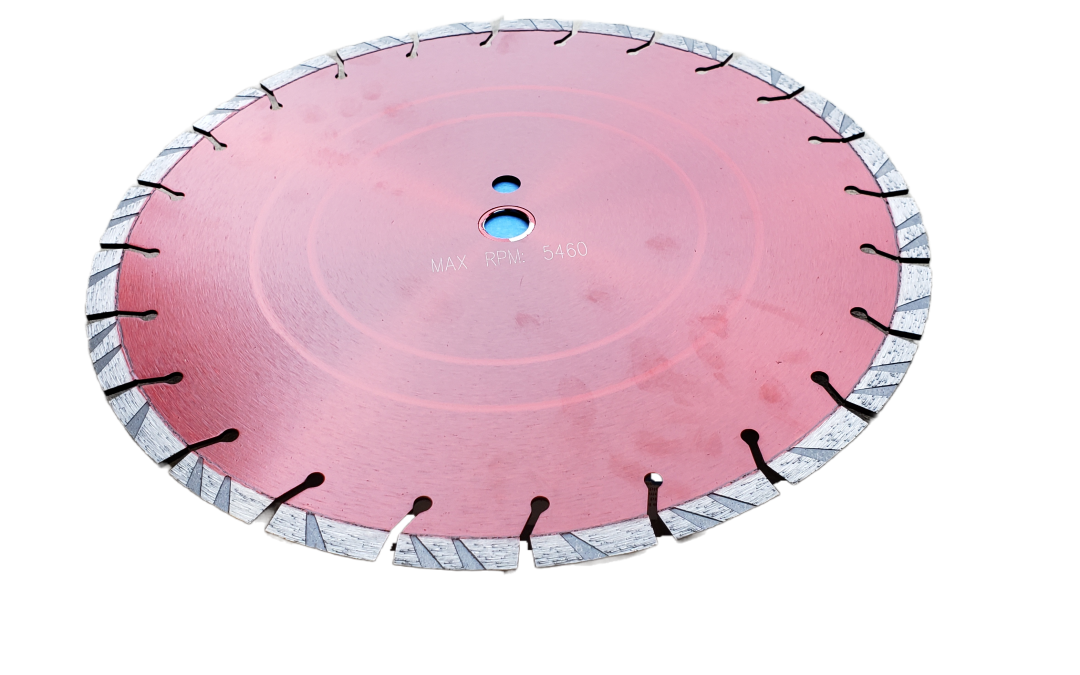

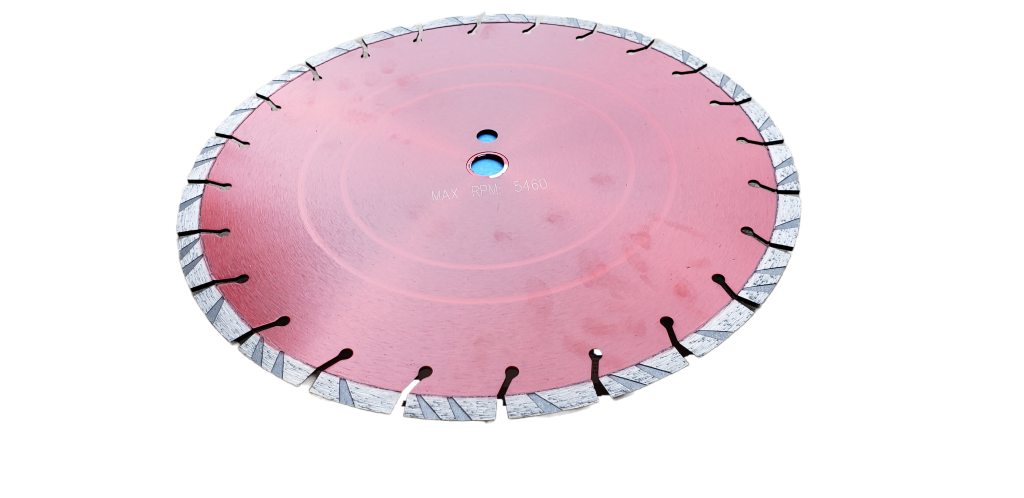

Laser Welded Diamond Blades: Pros and Cons

If you are a professional in the construction or building industry, then you probably know how important diamond blades are. They are the backbone of any cutting project, and they come in various types, including laser welded diamond blades. In this article, we will be exploring the pros and cons of laser welded diamond blades to help you determine if they are the right tool for your cutting needs.

What Are Laser Welded Diamond Blades?

Laser welded diamond blades are cutting tools that are designed to cut through hard materials such as concrete, granite, and asphalt. They are made by welding diamond segments onto a steel core using laser technology. The laser beam melts the metal, creating a strong bond between the diamond segments and the core. This process ensures that the diamond segments do not detach from the core, ensuring maximum safety and efficiency during cutting.

Pros of Laser Welded Diamond Blades

- Long Lifespan

One of the biggest advantages of laser welded diamond blades is their long lifespan. They are designed to withstand high temperatures and heavy use, which makes them ideal for large projects. They are also resistant to wear and tear, ensuring that you get the most out of your investment.

- High Cutting Speed

Laser welded diamond blades are also known for their high cutting speed. They can cut through hard materials quickly and efficiently, saving you time and money. This makes them ideal for large projects where time is of the essence.

- Versatility

Laser welded diamond blades are versatile and can be used to cut through various materials, including concrete, granite, and asphalt. This makes them ideal for contractors who work on different projects.

- Safety

Laser welded diamond blades are designed to be safe to use. The laser welding process ensures that the diamond segments do not detach from the core, reducing the risk of accidents. They are also less likely to break during use, reducing the risk of injury.

Cons of Laser Welded Diamond Blades

- Cost

One of the biggest drawbacks of laser welded diamond blades is their cost. They are more expensive than other types of diamond blades, which can be a barrier to entry for some contractors.

- Cooling System Required

Laser welded diamond blades require a cooling system to prevent overheating during use. This can add to the cost of the blade and may be inconvenient for some contractors who do not have access to a cooling system.

- Limited Wet Cutting

Laser welded diamond blades are not ideal for wet cutting, which can limit their use in certain projects. They are designed for dry cutting and may not perform as well when used with water.

- Risk of Warping

Laser welded diamond blades are at risk of warping during use. This can cause the blade to lose its shape and reduce its cutting efficiency. It is important to use the blade correctly to avoid warping.

Conclusion

Laser welded diamond blades are an excellent choice for contractors who work on large projects and need a cutting tool that can withstand heavy use. They offer a long lifespan, high cutting speed, versatility, and safety. However, they do come with some drawbacks, including cost, the need for a cooling system, limited wet cutting, and the risk of warping. It is important to consider these factors when deciding if laser welded diamond blades are the right tool for your needs.

FAQs

- Can laser welded diamond blades be used for wet cutting? Answer: Laser welded diamond blades are not ideal for wet cutting and are designed for dry cutting.

- How long do laser welded diamond blades last? Answer: Laser welded diamond blades offer a long lifespan and are designed to withstand heavy use.

- Do laser welded diamond blades require a cooling system? Answer: Yes, laser welded diamond blades require a cooling system to prevent overheating during use.

- Are laser welded diamond blades expensive? Answer: Yes, laser welded diamond blades are more expensive than other types of diamond blades.

- What is the risk of warping with laser welded diamond blades? Answer: Laser welded diamond blades are at risk of warping during use, which can reduce their cutting efficiency. It is important to use them correctly to avoid warping.

If you are in need of the Highest Quality Diamond Blades on the market, look to Quality Diamond Blades. Free Shipping on orders over $100

Call us today and we can walk through your next project so you have the right diamond blade for the job. Thanks for looking at Laser Welded diamond blades!